Selecting the right PLM software shapes how businesses design, produce, and manage products throughout their entire lifecycle. This decision directly influences efficiency, collaboration, and innovation. Understanding key features and vendor strengths helps align software capabilities with unique operational needs—turning digital transformation goals into measurable business results.

Essential Guide to Product Lifecycle Management Software: Features, Benefits, and Top Solutions

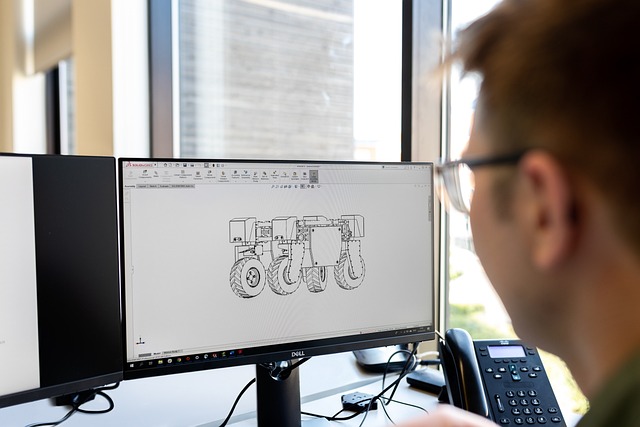

Modern product lifecycle management (PLM) software has reshaped how organizations streamline the entire journey from a product’s ideation to its retirement. For a deep dive into selection strategies, Access the full content here. At its core, PLM provides a digital backbone that enhances collaboration, automates workflows, and secures intellectual property. Early-stage PLM primarily managed CAD data, but contemporary solutions unify product development, quality control, and supply chain operations through a single source of truth.

This might interest you : Is the Future of High-Tech Spurring Investment in UK Computing?

Today’s PLM tools offer robust features—such as digital bill of materials (BOM) management, engineering change management, and process automation—for improved product accuracy and rapid response to market needs. Core benefits include minimizing errors, boosting cross-functional teamwork, and enabling faster, data-driven decisions.

Industry leaders like Siemens Teamcenter and PTC’s Windchill set benchmarks with their scalable, flexible platforms, serving sectors from aerospace to electronics. Siemens Teamcenter, for instance, connects design, engineering, and manufacturing teams, while Windchill drives traceability and compliance throughout the lifecycle. Major solutions are evolving, with cloud-based PLM, integration with IoT and digital twins, and enhanced analytics transforming business outcomes and enabling ongoing innovation.

In the same genre : Top plm software options to enhance your business success

Comparing PLM Solutions and Key Considerations for Selection

When evaluating a plm system for your business, examine how solutions like teamcenter software and windchill software address your requirements for data continuity, collaboration, and integration. Engineering plm platforms such as these centralize product information, supporting efficiency gains in both the design and manufacturing processes. Typical use cases for top plm system comparisons involve managing complex product lifecycles, from development to ongoing support, especially in sectors needing stringent traceability and regulatory compliance.

Seamless integration with enterprise systems—ERP, MES, IoT—is vital for digital transformation. Many plm for manufacturing industry solutions provide out-of-the-box connectors and configurations to ensure data flows smoothly across systems. Whether implementing teamcenter cloud solutions or hybrid deployments, aligning IT infrastructure and training with user needs leads to smooth adoption.

Assessing plm software cost considerations is essential. Key factors include initial licensing, ongoing support, scalability, and deployment choices (cloud, on-premises, or hybrid). Market leaders differentiate through flexible licensing, deep industry support, and robust training services—ensuring your investment in a plm system supports both current and future business goals.

Successful Adoption and Industry Applications of PLM

Collaborative product development thrives when organizations deploy targeted plm user adoption tips to engage multidisciplinary teams. Ensuring early executive sponsorship and deploying structured plm training and certification are proven methods for maximizing participation. Clear communication about benefits, role-specific guidance, and accessible documentation break down barriers, helping product development teams leverage the full spectrum of plm solutions. Resistance often comes from process changes, but dedicated adoption resources and ongoing feedback channels drive success.

Best practices for boosting PLM adoption across diverse teams and mitigating challenges

Promoting a single digital thread fosters synchronized collaboration, especially across global or remote product development teams. For plm for discrete manufacturing, embedding collaborative product development workflows ensures transparent engineering change management and quicker issue resolution. Engaging cross-functional stakeholders directly within apparel plm system environments empowers decision-making and reduces miscommunication.

Real-world case studies on PLM-driven digital transformation

The fashion industry plm solutions landscape shows leading apparel brands and manufacturers dramatically improving efficiency and speed-to-market. Companies integrating plm software for apparel brands and plm solutions for apparel manufacturers report measurable agility boosts, echoing similar gains found in aerospace and electronics through digital twin integration with PLM and simulation software with PLM.

Emerging trends: Digital thread, digital twins, and AI-enhanced PLM

Digital twin integration with plm streamlines iterative product improvements, while simulation software with plm offers predictive modeling—significant for fashion and discrete manufacturing sectors. Looking forward, AI augments PLM by delivering smarter reporting and analytics, automating repetitive tasks, and enhancing collaboration across every stage of the product lifecycle.